Let us work together to create more possibility of coating techonology

2022.10Coating skill means via device to make liquid glue be distributed on base material. There are many way of coating, such like Scraper, Micro-gravure, Gravure, Slot die etc. it depends on property and feature of glue, no matter which coating way, the purpose is to ensure the glue can get good distribution. How to find the most suitable way for coating? Let ITSM rules helps you .

Inquiry of coating glue : according to basic information to find the best coating way

Based on adhesive and polymer type, solvent, viscosity, solid content, particle size, coating width and thickness etc., we can evaluate which coating or which design of slot die to be suitable for customer.

- adhesive and polymer type is relative with application.

- Coating width and thickness decide slot die width.

- Viscosity is relative geometric design of channel, meanwhile, coating thickness can be complied or not depends on viscosity.

- Coating thickness, solid content and particle are addition for revising coating process.

Test : Pilot machine provide you lowest cost, but bring you the best benefit

External flow field variable

Coating glue: viscosity, surface tension, polymer combination ingredients

Slot die: lip gap, landing area design

Process: roll diameter, line speed, wet film thickness, coating gap

(besides coating glue and slot die, process is also important reference information.

Compared with other companies, GMA build multifunction coating laboratory, equip with pilot machine, interchangeable coater device for different coating process test, such as 300mm slot die, comma, roller reverse gravure, microgravure etc., meanwhile, GMA coating team has more than 20 year coating process experience, provide solution and technology support for test.

GMA provide pilot machine for test, meanwhile, senior coating engineer provides technology support.

One of our customer want to revise their coating way from gravure to slot die, but they was facing a big problem, they had no idea how to evaluate the benefit of slot die, GMA team suggested and arranged them a test, only 3kg glue for the test, soon, they got useful operation condition and some sample for their reference, based on the test, they had objective evaluation.

They decide to replace all gravure device to slot die, over ten coating line, Slot die excellent performance is not only to save their a lot time and cost, meanwhile, the coating tolerance narrow from 5% to 2%.

GMA team provide test to help customer, as lowest test cost but bring the best benefit.

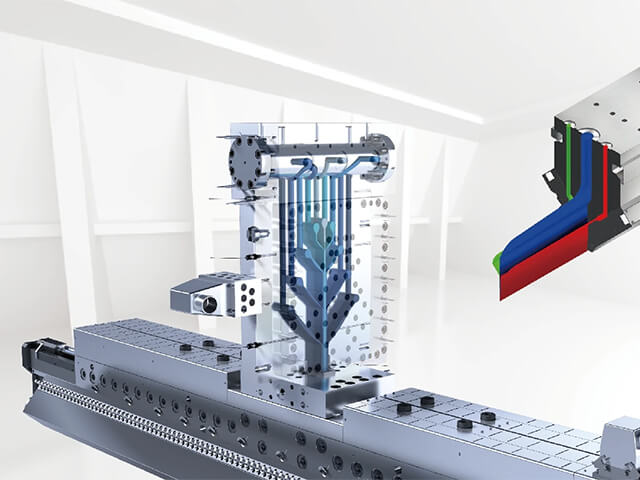

Simulation : Optimized channel of slot die, excellent performance

Slot die is listed as one of external flow field variable factor, because coating quality depends on slot die design. For reducing variable risk, via simulation software, we can analysis how the pressure and distribution variety, when glue in the die chamber, through the simulation result to find the most suitable channel geometry design for processing glue, ensure even coating layer.

Through simulation software, we can analysis the glue distribution, optimized geometry design of channel.

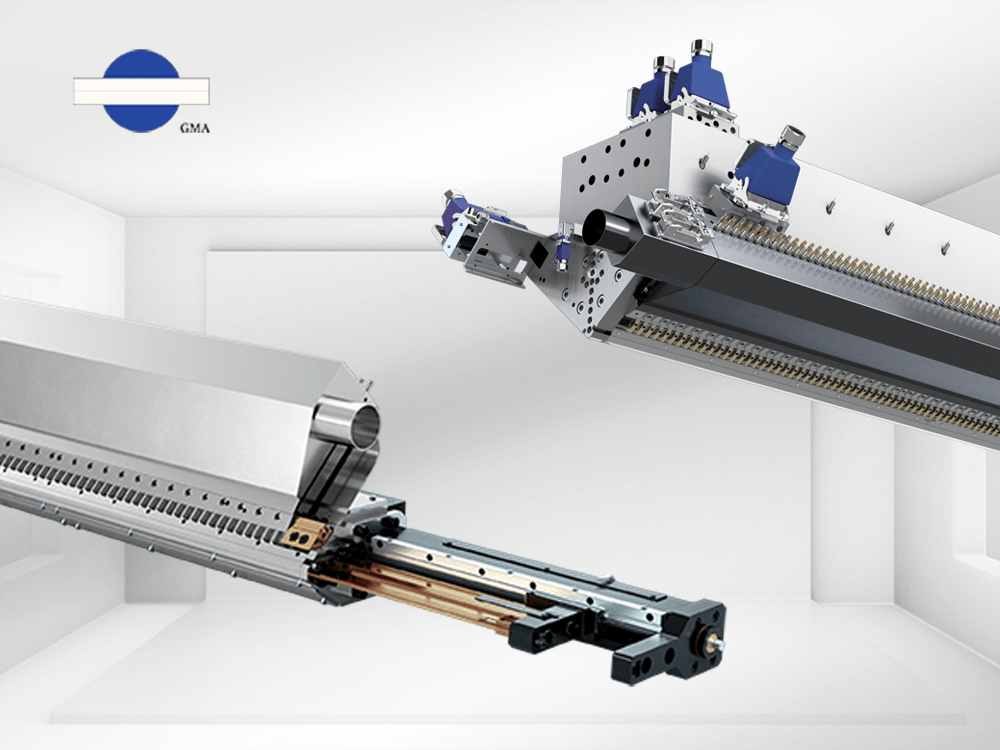

Manufacture: precision slot die come from great processing and strict inspection

Slot die is absolutely the essential factor of coating quality, as people know that slot die is a core technology of coating process, based on such importance of slot die, the precision of surface of die is the most important point, if there is any defect, even slight flaw, people say that “glue always remember the flaw and bring you more flaw.” It must cause some blemish, such like coating layer line or bubble etc.,

For avoiding from this problem, we have standard processing, first, take patent stainless SUS630 steel for making slot die; second, advance CNC machine and grinding machine for processing, straightness and lip surface flatness can be controlled in 2.5mm, surface roughness of lip is under Ra0.03um, third, before shipping, we execute strict inspection, meanwhile, provide the inspection report to customer.

GMA strict processing of manufacturing die, ensure slot die great precision and performance.

Coating technology is wild applied on optional, medical, lithium battery, semiconductor industries, it also core technology, from equipment and technology, GMA provide customer completely support, stay with you as the best partner, let’s work together to create more possibility of coating technology.