AI and New Energy: Twin Engines Driving Future Technology

2024.05.31When discussing the most talked-about topics today, besides AI technology, the new energy agenda stands out. One of the most well-known AI applications is the rapid iteration and update of ChatGPT. The new generation of ChatGPT can handle an increasingly diverse range of tasks, which means that the computation of large AI models and chip transmission speeds must also keep pace. In this context, the semiconductor industry, a key driver of pioneering technology's rapid development, plays an indispensable role.

Application of Photoresist Coating Technology

The commonly heard term "chip" refers to the product obtained after complex processing of raw materials. These complex processes give rise to the so-called semiconductor industry chain, which can be divided into upstream, midstream, and downstream. From the front-end IC (Integrated Circuit) design, midstream manufacturing, to the final packaging and testing, the midstream IC manufacturing involves processes such as coating, applying photoresist, photolithography, development, and etching.

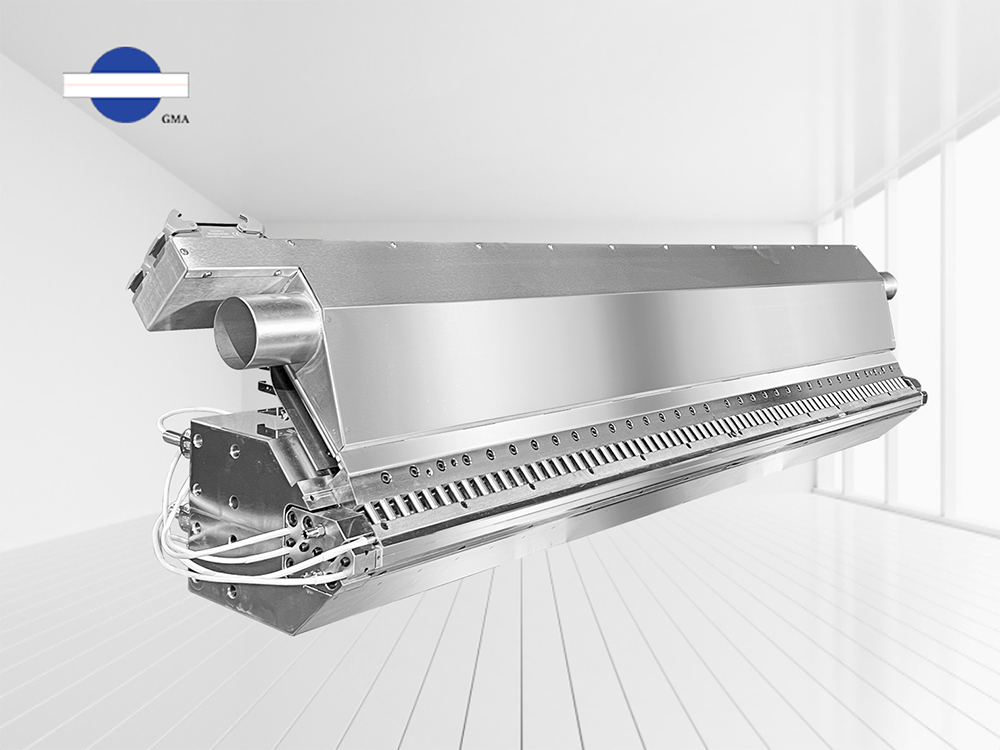

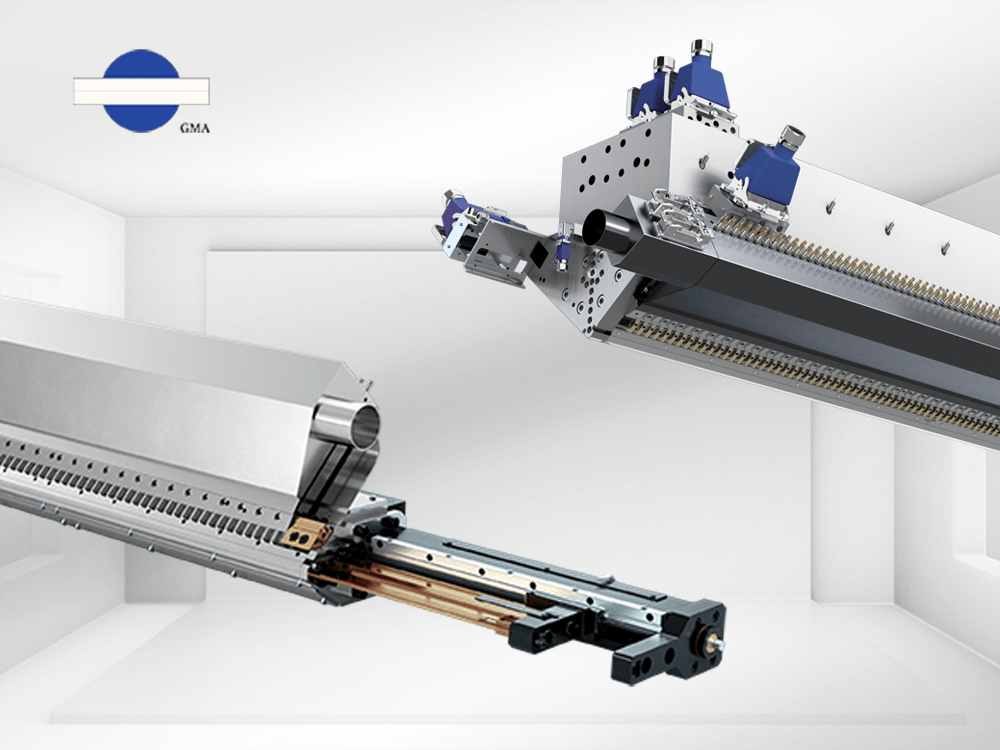

Among these, photoresist coating is one of the crucial processes. Photoresist is a light-sensitive material that undergoes chemical changes when exposed to ultraviolet light or other light sources. The quality of photoresist coating affects subsequent IC processes, especially given the increasing precision required by high-tech products today, highlighting the importance of photoresist coating.

The photoresist coating technique is a key process in many industries.

However, coating technology is not only used in the semiconductor industry. In the manufacturing processes of 3C-related products, it has led to the development of both dry and wet coating methods. For example, color photoresist, which is primarily used in flat panel displays, significantly impacts the color performance of displays. Therefore, it is widely used in various panel products. As panel sizes increase to meet market demand, the challenge is how to make coatings thinner and more uniform over large substrates. Factors such as coating height, speed, and the viscosity of the photoresist are crucial, making the related equipment and technology a mainstream trend for the future.

There are many factors to consider for achieving uniform coating on large-area substrates.

Rise of Perovskite Batteries: The Next Boom in the New Energy Market

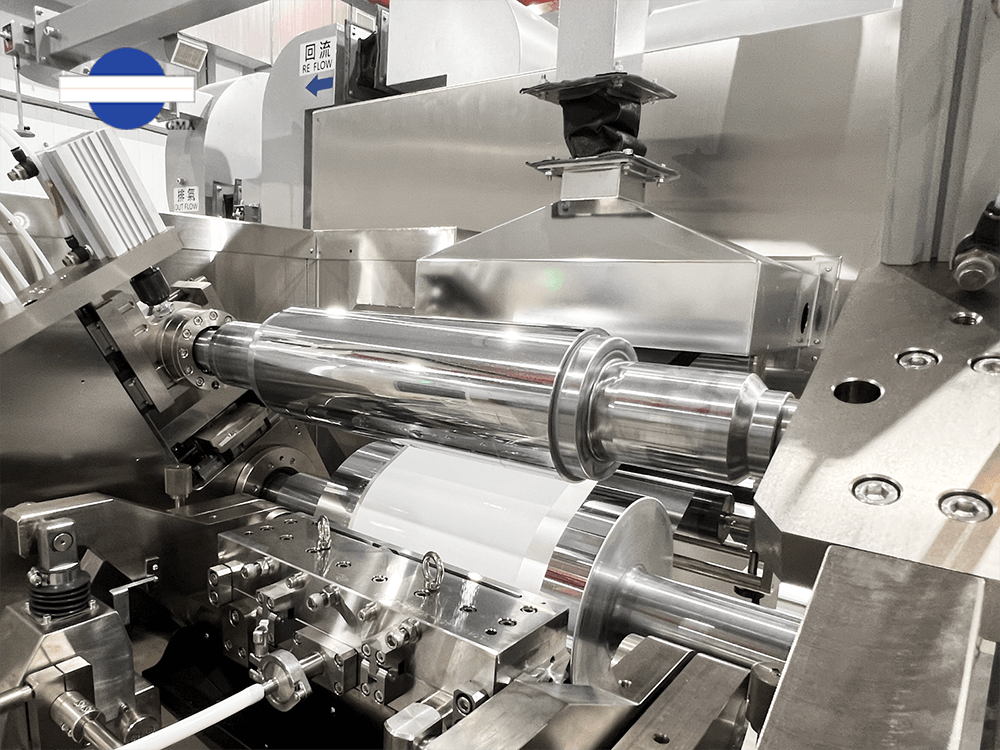

Technological advancements have also brought about new material applications. With global advocacy for energy conservation and zero carbon emissions, not only has the electric vehicle market risen, but it has also driven the application of new energy sources. The lithium batteries used in electric vehicles must meet various considerations, such as long-term energy storage and efficiency. Improving energy conversion has become a key technology, and the coating of the positive and negative electrodes also plays a significant role.

Coating in the process of manufacturing lithium batteries for

automobiles impacts various performance aspects of the batteries.

Coating in the process of manufacturing lithium batteries for

automobiles impacts various performance aspects of the batteries.

Learn more: Key point of lithium-ion battery : coating technique

In addition to lithium batteries for electric vehicles, photovoltaic (PV) cells, also known as solar cells, are another focal point in the global new energy application field. Solar power generation is not a new technology; it was developed in Europe as early as 1969, converting sunlight into electricity. Over the years, the use of solar cells has expanded from Europe to the rest of the world. Especially in the current context of high energy demand, solar power is a renewable and environmentally friendly way of generating electricity. With various governments promoting the use of solar energy through incentives or tax reductions, related technologies have continually evolved and expanded into commercial applications.

Japan has been one of the most proactive countries in promoting solar energy, and China has also seen significant growth in its photovoltaic industry. This is partly due to strong government support and subsidies for solar photovoltaic buildings, which have spurred the industry's development in China.

Solar cells can be classified based on the materials used into silicon-based semiconductor cells, thin-film cells, and organic material cells. Regardless of the materials used, the key challenge is how to improve the energy conversion efficiency of solar cells. The development of solar cells has seen four different generations:

1. First Generation: Primarily based on silicon wafers, this generation is currently the most technologically mature.

2. Second Generation: Known as thin-film solar cells, these are produced using thin-film manufacturing processes.

3. Third Generation: These solar cells incorporate organic materials and

nanotechnology into the manufacturing process.

4. Fourth Generation: This generation improves light absorption through multilayer thin-film structures.

Solar cells are currently experiencing vigorous development, and improving conversion efficiency will be key to future advancements.

Currently, silicon-based solar cells on the market have an energy conversion efficiency of around 15-20%. Thin-film solar cells also achieve a similar efficiency of about 15%. In simple terms, regardless of the type, solar cells' efficiency does not exceed 20%. However, the so-called third-generation "perovskite" cells have rapidly developed in technological advancements, reaching high energy conversion efficiencies of 23-25%. This has made them a focal point in the market. Additionally, perovskite materials have lightweight and semi-transparent physical properties, making them easy to coat on various substrates. They are widely used in building facades, electronic products, car surfaces, etc. Moreover, their production costs are lower compared to other types of batteries, making perovskite cells gradually enter the commercial market as a major advantage.

Due to the advantages of perovskite cells, according to survey data, the global market for perovskite batteries was around $600 million in 2021, expected to reach about $7 billion by 2023. It might hit its first peak in 2025. Japan, which pioneered this technology, has seen several companies continuously investing in research and development. This opportunity has attracted more global players to join the competition, actively adopting perovskite technology and equipment. Although there are challenges such as the shorter lifespan of perovskite batteries (about 5-8 years compared to traditional solar cells' 20-year lifespan) and performance variations as the battery size increases, some companies in the market are planning to mass-produce A4-sized perovskite solar cells. Achieving this goal requires overcoming technical challenges and investing in production equipment, as achieving uniform coating over large areas for mass production requires significant research and development expenditure and time.

AI and the development of new energy are indeed becoming powerful forces leading future trends. Optimizing key processes such as photoresist coating and perovskite coating can drive this wave of innovative revolution. The progress in technology and the utilization of new energy sources are poised to change our lives, offering a myriad of limitless possibilities.