Key to Building Quality Extrusion Dies: Advanced Precision Machining Techniques and Team Collaboration"

2024.11.28CNC (Computer Numerical Control) machining is a well-known precision machining process. Its features, such as achieving precise machining through computer calculations, wide application range, and high efficiency, make it a crucial factor for many precision manufacturing companies in advancing their manufacturing technologies.

The manufacturing process for extrusion dies is complex and involves numerous steps, with each stage closely interlinked in terms of precision. CNC machining, which constitutes a significant portion of the process, is the most capable of meeting the diverse requirements of different steel materials and various lathe and milling operations. For die materials, they can generally be categorized into mold steel, stainless steel, and specialty steels, such as Hastelloy.

CNC machining, which accounts for a significant portion of the extrusion die manufacturing process, is highly adaptable to various steel materials and multiple lathe and milling operations. This includes mold steel, stainless steel, and Hastelloy (shown on the right in the photo).

Hastelloy® C276 alloy (UNS N10276) is one of the few alloys resistant to wet chlorine gas, hypochlorite, and chlorine dioxide solutions. It exhibits excellent resistance to strongly oxidizing salt solutions, such as ferric chloride and cupric chloride. Known as one of the most corrosion-resistant alloys available today, it is widely used in applications such as pressure vessels, high-temperature and high-stress nuclear reactor components, chemical reaction equipment, pipelines, and valves in the chemical and aerospace industries. Its outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking makes it a superalloy of choice for demanding environments.

However, due to its challenging machinability, Hastelloy is often referred to as a "devil material." Compared to other die steels, the high heat generated during contact between the cutting tool and Hastelloy causes rapid hardening (work hardening from cutting heat). This leads to tool damage or reduces tool lifespan by up to 30%. Machining efficiency is significantly reduced by 50–60% compared to other steel materials, and achieving precise machining tolerances becomes extremely difficult.

Hastelloy, often referred to as a "devil material," can damage both the cutting tool and the material itself if inappropriate tools are used.

With extensive experience, the optimal cutting conditions are determined by testing and matching various machining parameters and tools. Starting with the tool substrate and coating, the ideal cutting oil concentration for machining this material is specially formulated. A low-temperature cooling cutting oil system is used to control the liquid temperature, reducing the cutting speed to 15–45 m/min. This is combined with conditions tailored to milling, turning, and drilling operations, ensuring that accumulated heat is dissipated through tool cooling or chip removal. This significantly minimizes the material's heat-hardening effect.

During the process, the feed rate and cutting speed for each operation and workstation are meticulously recorded and adjusted as needed. While the cost of specialized tools is relatively high, effective control over Hastelloy's machining quality and efficiency has yielded impressive results. The average tool lifespan has been extended by 25%, and machining efficiency is maintained at a reduction of less than 15%.

The selection of cutting tools is crucial in CNC machining. To meet different machining requirements, specialized and customized tools must be used.

Read more: How to select the suitable steel to manufacturing extrusion die ?

CNC machining operates through three dimensions (axes) using a variety of tools interchangeably. Each tool has its specific cutting angle and unique functions to achieve various machining results. The process begins with a programming engineer converting design drawings into machine-readable codes, setting all machining parameters such as tool usage sequence and angles. Then, an experienced mechanical engineer operates the machine.

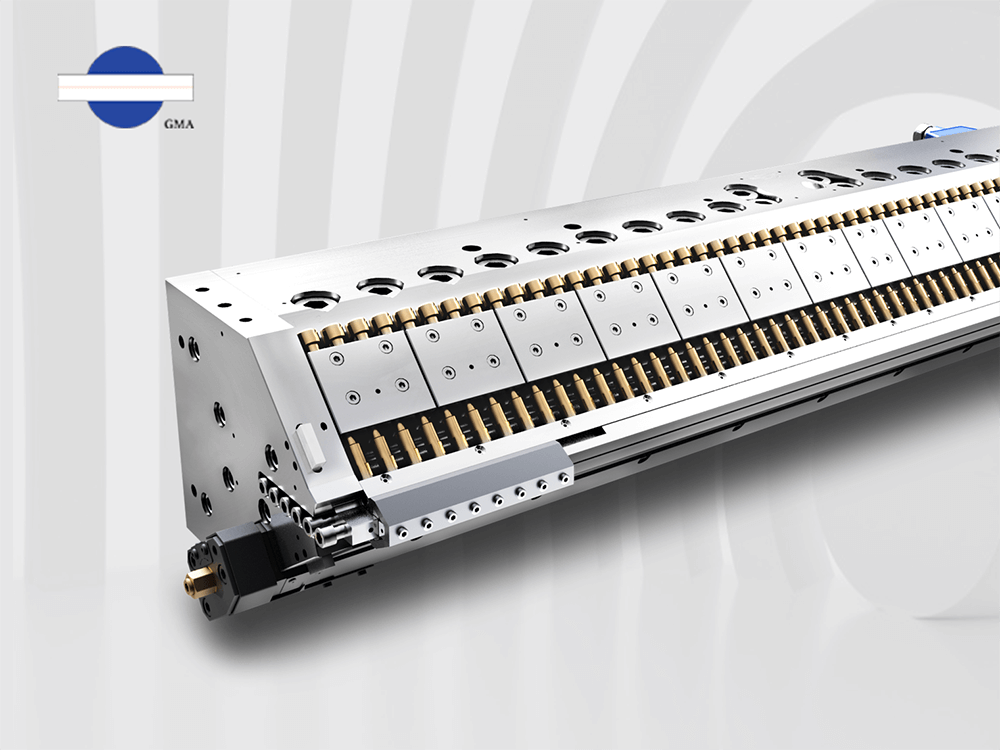

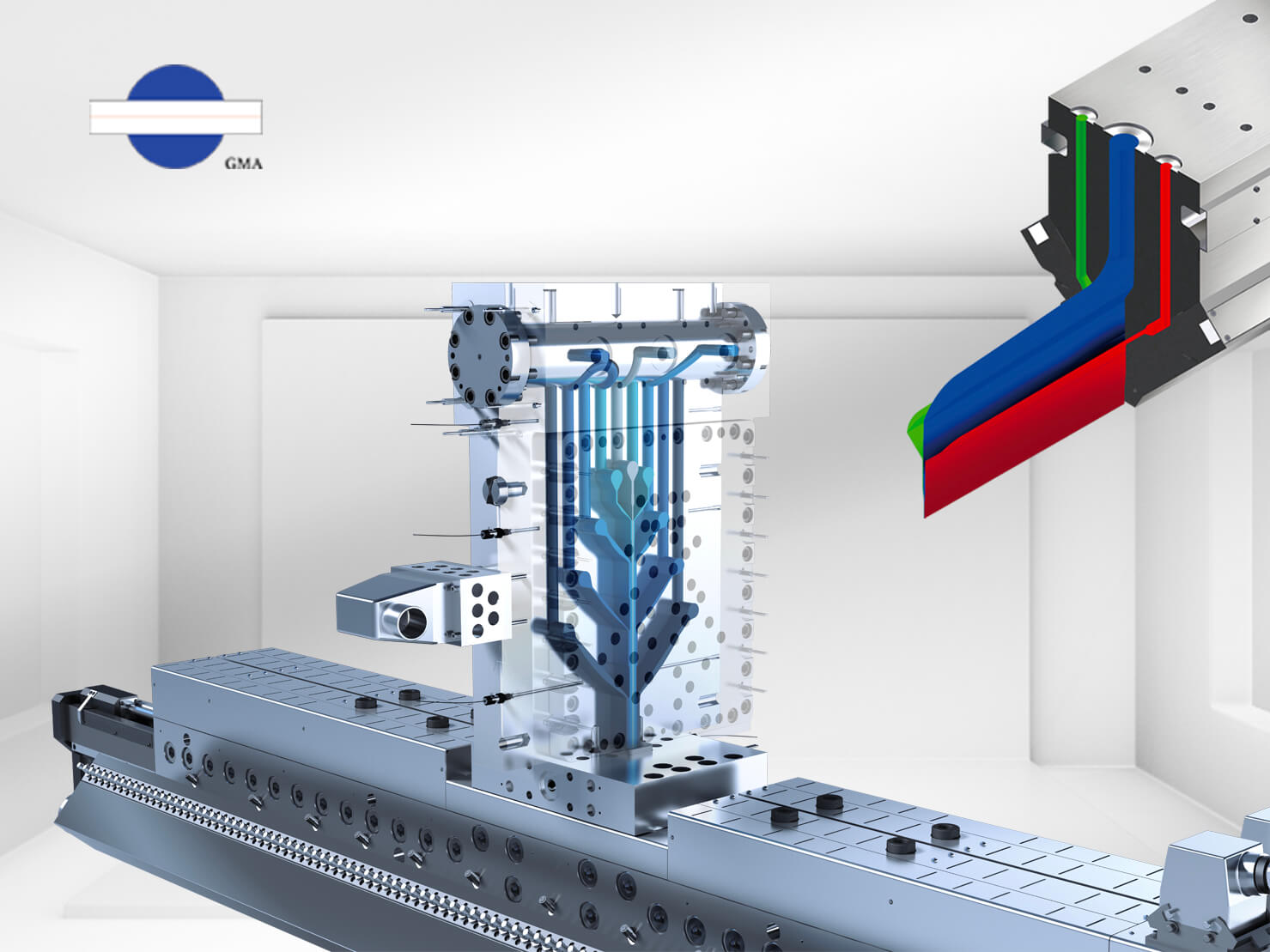

Taking extrusion die flow channels as an example, there are three main types of flow channel shapes. Some require straight, uniformly wide channels, while others may have semicircular shapes or varying depths, curvatures, and angles. Consequently, machining a single set of flow channels might involve switching between multiple tools. The machining process must precisely adhere to the design's allowable tolerances, as the flow channel design ensures the uniform distribution of plastic within the die cavity.

To achieve this, close collaboration among the design team, programming engineers, and mechanical engineers is essential. This coordination minimizes discrepancies between design and machining, preventing significant errors that could compromise the die's functionality.

The diverse variations and precision requirements of the flow channels inside extrusion dies are all achieved through CNC machining.

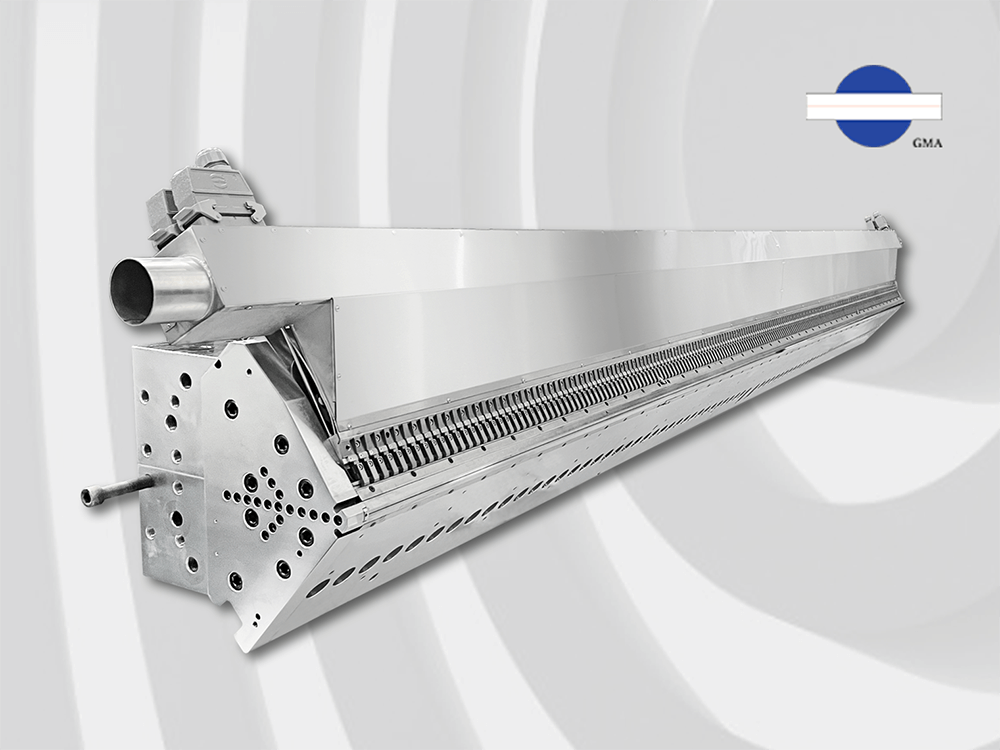

Due to CNC machining's ability to control tolerances within extremely small ranges—down to a level finer than a human hair (approximately 0.017mm)—the demand for equipment used to produce mask materials surged dramatically during the pandemic. The core meltblown and spunbond dies were traditionally dominated by a few manufacturers, and expanding production capacity quickly was impossible. In this situation, a highly experienced team, familiar with the precise capabilities of CNC machining, was able to mass-produce meltblown dies within 60 days to meet market demand.

The greatest challenge with meltblown dies compared to extrusion dies lies in the thousands of small holes, typically with diameters of 0.15-0.3mm and a depth-to-diameter ratio of 12-15 times. These holes are narrow and elongated, and the die’s outlet, filled with holes, must be integrally formed. The tool hardness must be sufficient to drill the holes, and the tool must be long and fine enough to complete the process. If even one hole is drilled incorrectly or misaligned, the entire steel block becomes unusable. To achieve precise drilling, the design, programming, and mechanical teams specifically developed custom tools for CNC machining to handle such specialized holes.

The discharge holes of meltblown dies are small and narrow, and are manufactured using specialized tools and CNC machining techniques.

With up to fifty CNC machining machines of various sizes, the goal is to meet diverse machining requirements. To effectively manage the use of these machines, an intelligent management system is employed, enabling more precise production scheduling and making it easier for operators to handle the equipment.

The intelligent system management ensures more precise scheduling, effectively utilizing equipment to enhance machining quality.

To improve the actual performance of molds, in addition to CNC machining, polishing, grinding, and electroplating optimization are indispensable processes. CNC machining ensures the precision of the workpiece dimensions, while other processes refine every detail of the mold. For coating molds, different design structures are provided based on varying usage requirements.

The primary concern with coating molds during use is the formation of surface lines and damage to the lips. High-precision polishing and electroplating inside the mold cavity can reduce the occurrence of lines, but lip damage is often caused by human cleaning errors. Although this is not the responsibility of the manufacturer, to help users minimize the risk of operational mistakes, special processing treatments are employed to significantly reduce the risk of lip damage. This approach has received positive feedback from many users.

Read more: Rough? Not at all! The surface roughness is more detailed than you can imagine.

For extrusion dies used in special applications, such as PPF (TPU automotive protective film) production lines, optical product molds, and coating-specific molds, not only do the designs differ, but they also incorporate CNC machining, specialized electroplating techniques, or other unique processes. These molds, designed based on specific needs, are 100% realized through precise machining. The combination of design, programming, mechanical operation, electroplating, polishing and grinding expertise, quality control, and assembly technician teamwork showcases the complete production process. This collaborative effort forms the essential foundation for ensuring stable quality.

The collaboration of design, programming, mechanical operation, electroplating, polishing and grinding experts, quality control, and assembly technicians demonstrates how a complete production process can fully realize molds designed for different needs. This is also a crucial foundation for ensuring stable quality.

Read more: Enhance PPF Quality: Focus on TPU Film Coating Production and Composition

In summary, a seamless, comprehensive machining process, combining intelligent management and the collaborative efforts of a professional team, is essential for successfully tackling various challenges and achieving high-performance, reliable molds. In the future, with continuous advancements in technology, we will continue to refine our processes, using more efficient and innovative machining methods to provide customers with high-quality extrusion dies solutions that meet their needs.