Technological Breakthroughs for Seamless Production—How They Found the Key to Success!

2025.02.27Regarding the yield dilemma

Company T specializes in the production of optical films. To maintain high yield rates and control costs while operating at full capacity, they require backup extrusion dies as critical components to ensure smooth production. However, finding a supplier that meets their stringent requirements while providing fast service has proven to be a significant challenge. At the same time, due to a shortage of manpower on the production line, the personnel originally assigned to maintenance and servicing had to be reassigned to shift work on the production line. Without dedicated maintenance support, the uninterrupted production line faced even greater pressure.

The yield of optical products is closely related to high-quality equipment and processes.

Regarding the bottleneck in technical equipment

Company D was planning a new production line for a long-term client to meet the demands of a new product. However, during production, excessive die pressure led to extreme instability in product quality, making it difficult to control. In response, the client adjusted the formulation, and Company D modified certain design aspects, but the improvements were minimal. They attempted to replace the flat die but were unable to find a die manufacturer that could provide an effective solution. As the client imposed a strict deadline for improvements, Company D's team found themselves in a difficult predicament.

Bottlenecks in equipment and technology often prevent improvements in production quality

Regarding the dilemma of research and development.

Company A, aiming to expand into a new coating business sector, conducted extensive evaluations and analyses of the relevant technologies and market potential through its R&D and marketing teams. They believed that entering this market would create significant opportunities for the company. However, some technical challenges still needed to be overcome, and sample production was necessary for essential testing. Investing in a full-scale production line would impose a heavy financial burden on the team, and the timeline for resolving certain technical issues remained uncertain. If they had access to coating equipment capable of producing samples and a small-scale production line to support potential low-volume manufacturing, they could overcome R&D bottlenecks while seizing market opportunities.

When venturing into a new field or new product, there will always be layers of hurdles that need to be overcome."

In the conference room, a team composed of members from design, sales, manufacturing, technical, and after-sales service departments was actively discussing how to help these three companies overcome their challenges.

The best support for stable quality and production capacity—high-precision molds and comprehensive services.

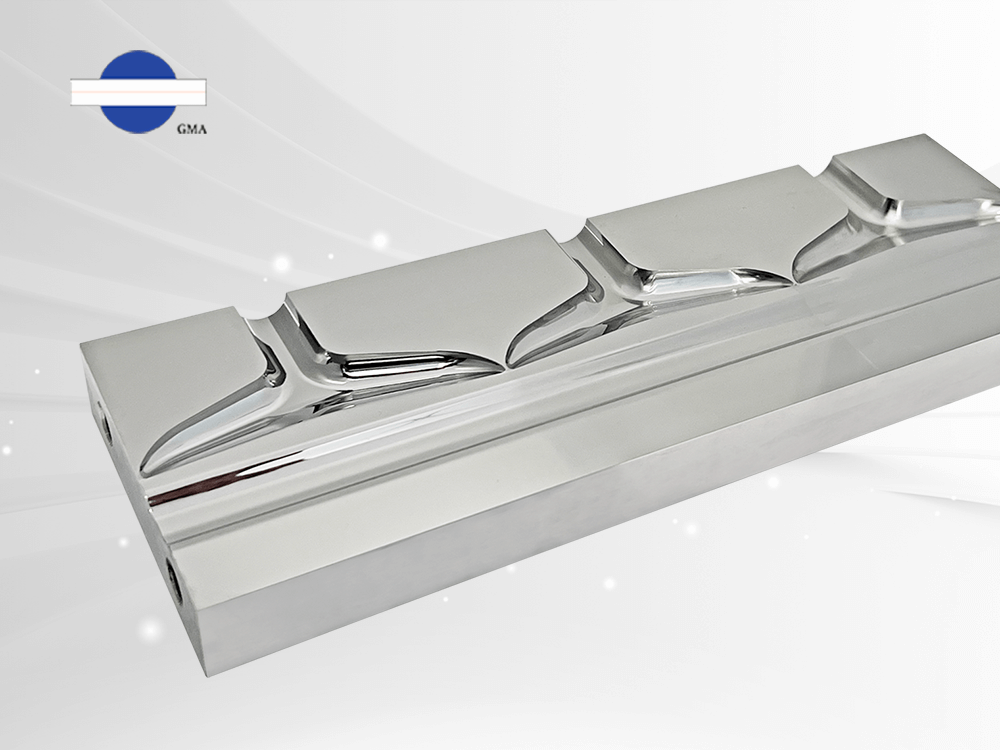

"For optical products, precision machining and high-accuracy extrusion dies are essential to maintaining stable yield rates and production capacity," the plant manager of Company T told us. After touring our facility, he was highly confident in our comprehensive process, from design to manufacturing. Our ability to control the critical aspects of die design ensured machining precision, and our rigorous quality control guaranteed that delivery timelines aligned with Company T’s requirements for backup optical extrusion dies. What satisfied Company T the most was the comprehensive service our team provided.

From design to manufacturing, mastering the complete process.

Not only did we provide after-sales service for extrusion dies, but we also offered routine maintenance, cleaning, and damage repair services. For Company T, these services effectively resolved their dilemma—ensuring equipment uptime and operational efficiency without increasing budget or manpower. The plant manager of Company T couldn’t help but express his relief, saying:

"Our dies are like the engines driving production, especially for optical products, where precision is closely tied to equipment performance. In the past, we always worried that any die issues could impact yield rates, leading to incalculable losses. Now, we've finally found a reliable maintenance partner, and we no longer have to be on edge, fearing that production capacity might be affected!"

Providing comprehensive services including after-sales support, routine

maintenance and cleaning, as well as repairs.

Providing comprehensive services including after-sales support, routine

maintenance and cleaning, as well as repairs.

Read more:All extrusion die issue , let GMA help you.

Innovation spirit and accumulated experience to find breakthroughs in technological and equipment bottlenecks.

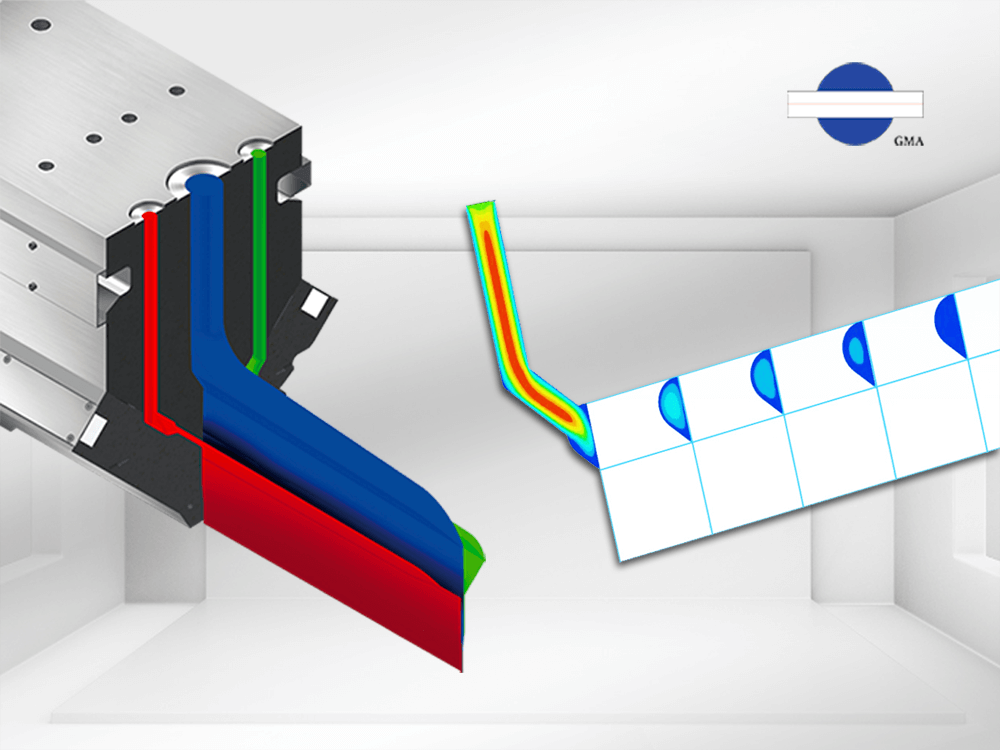

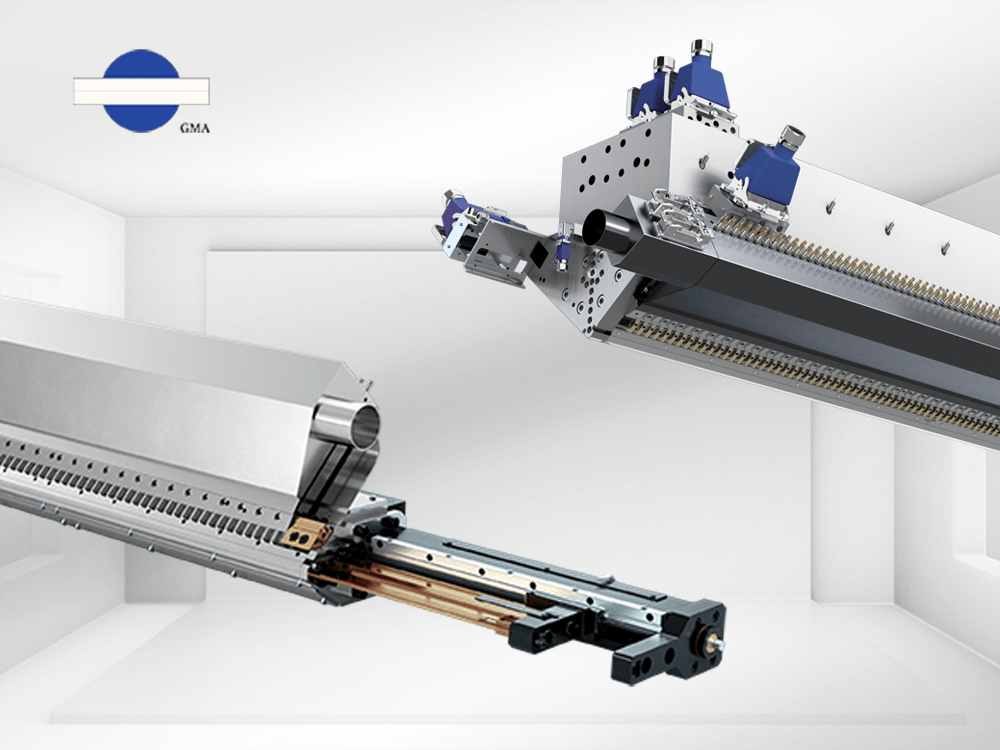

The CEO of Company D traveled a long distance to personally evaluate whether we could provide flat dies that met their requirements. During the short but intensive visit, he spent most of his time discussing with our flow simulation and flat die design teams. Through simulation analysis, we assessed the material properties used by the client, while also considering their production capacity needs, operating temperatures, and other manufacturing conditions.

Leveraging our experience from designing thousands of flat dies, our team identified the most suitable channel design module. We then conducted multiple rounds of optimization through simulation to refine the channel, ultimately developing an optimized flow channel design that resolved the issues of uneven thickness and excessive flat die cavity pressure.

Initially arriving with deep concerns, the CEO of Company D left with a smile after engaging in discussions and technical exchanges with our team, feeling reassured and pleased with the solution we provided.

Through

scientific analysis and experience, identify breakthroughs in technology and

equipment.

Through

scientific analysis and experience, identify breakthroughs in technology and

equipment.

Read more : Extrusion Die Design: From Theory to Practice

"I always remember the relieved smile on his face when he returned from the inspection at your company. He excitedly told us, ‘This is great! We’ve finally overcome our long-standing technical bottleneck.’"

Years later, a senior engineer from Company D’s team shared this with us. Over the course of several years of collaboration, our team has helped Company D resolve many challenging issues. One day, we received a letter of appreciation from their CEO, listing the names of all our team members. It was the most heartfelt and touching thank-you our team had ever received.

Team collaboration—bold innovation without fear.

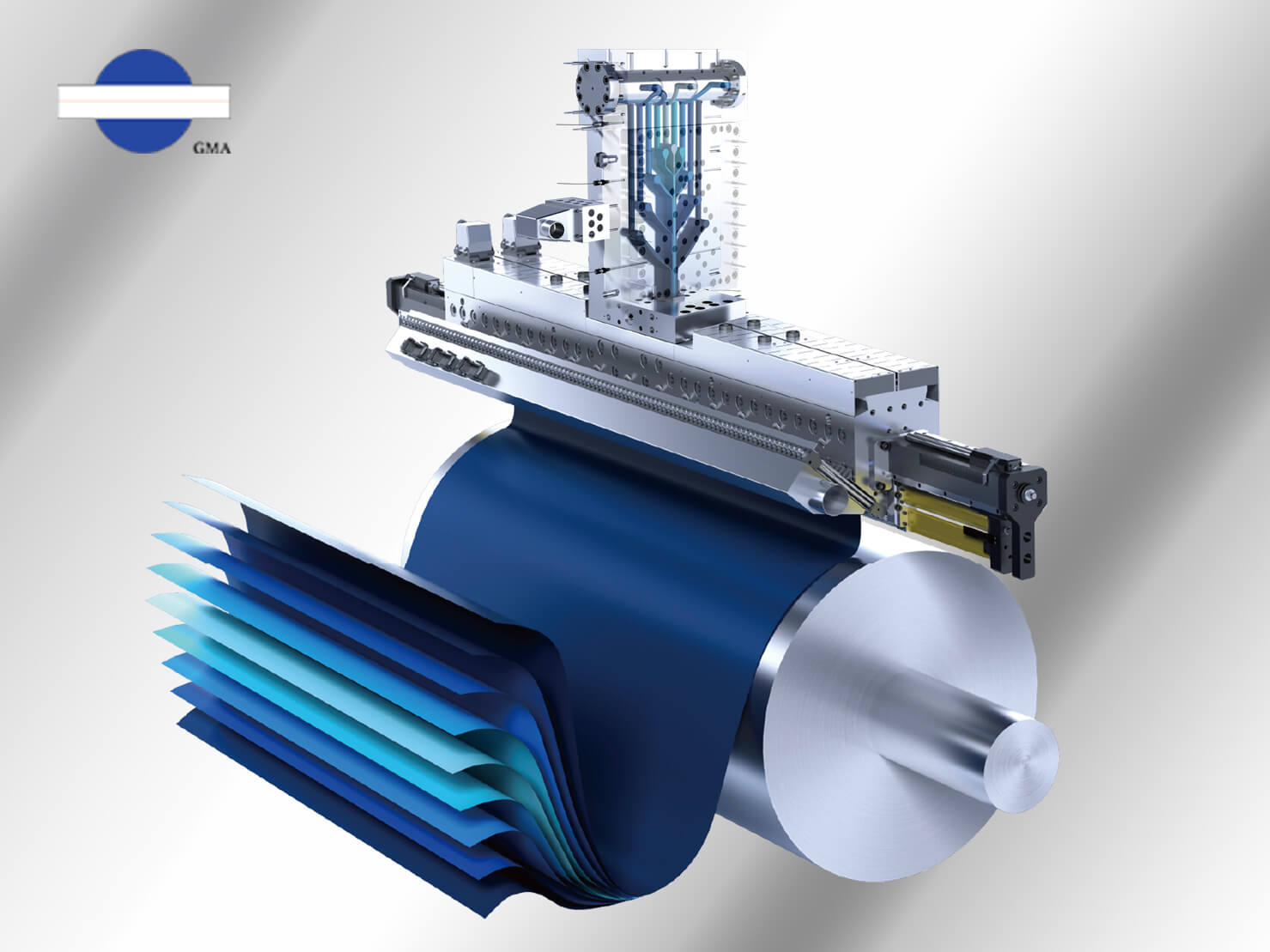

After several days of testing, the R&D director and engineers from Company A left with samples—samples that were produced using their own equipment that they purchased and their formulations. These samples are crucial for their future expansion into the coating market, as the competition in the coming years will be intense. Success will depend on high-precision coating technology—whoever can achieve high-quality products at lower costs will have the advantage. And quality comes from advanced equipment and optimized processes. Every decision they make will influence their market strategy and development direction.

Superior

equipment and optimized processes are the key to succeeding in a competitive

market

Superior

equipment and optimized processes are the key to succeeding in a competitive

market

Read more: Let us work together to create more possibility of coating technology

Before leaving, the R&D director told us, "The night before, when we held a video conference with our team to discuss this critical annual project, I told them how fortunate we were to have chosen you. Seeing your team’s dedication on-site, working tirelessly to make so many possibilities a reality for us, truly moved me. This has been one of the best decisions I’ve ever made!"

Reflecting on how the R&D director engaged in continuous discussions with our team—from coating production line design, process optimization, and raw material analysis to facility planning—we worked together to maximize production efficiency and explore the best possible configurations. At the end of all the testing, the R&D director stood up and shook hands with every team member involved, expressing his gratitude. For our team, months of effort were undoubtedly worthwhile.

We not only provide

equipment, but also serve as our customers' best technical partner.

We not only provide

equipment, but also serve as our customers' best technical partner.

Everyone knows that creating a great customer experience is essential. Every order represents a customer’s careful consideration, hope, and trust. Each order could be the realization of a dream. Our team’s mission is to be a partner and driving force in turning those dreams into reality—transforming innovative ideas into tangible products.

We don’t just provide equipment; we are our customers’ most reliable technical partner. If you have bold ideas, we welcome you to connect with us and embark on an exceptional customer experience journey!