Three common issues to the usage of extrusion die

2023.09

"With proper usage and regular maintenance, the average lifespan of an extrusion die typically ranges from 5 to 10 years. Based on data collected from thousands of users' experiences, the three common issues associated with the use of extrusion dies are as follows:

1.Leakage.

2.Flow marks and die lines.

3.Modifying the extrusion die.

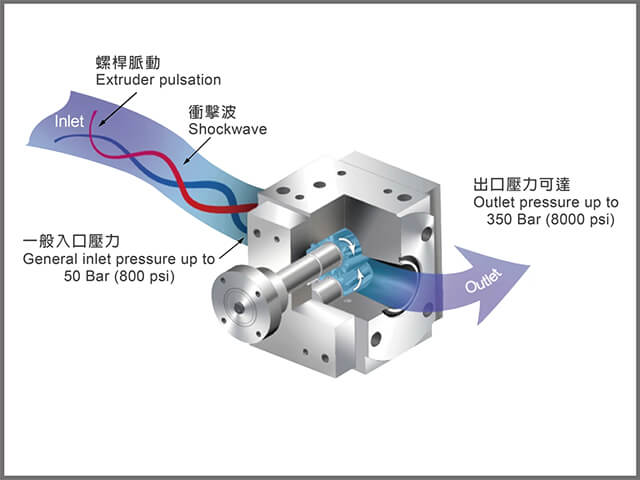

Leakage: often caused by incorrect operation of the deckle system, which includes adjustments for both width and thickness

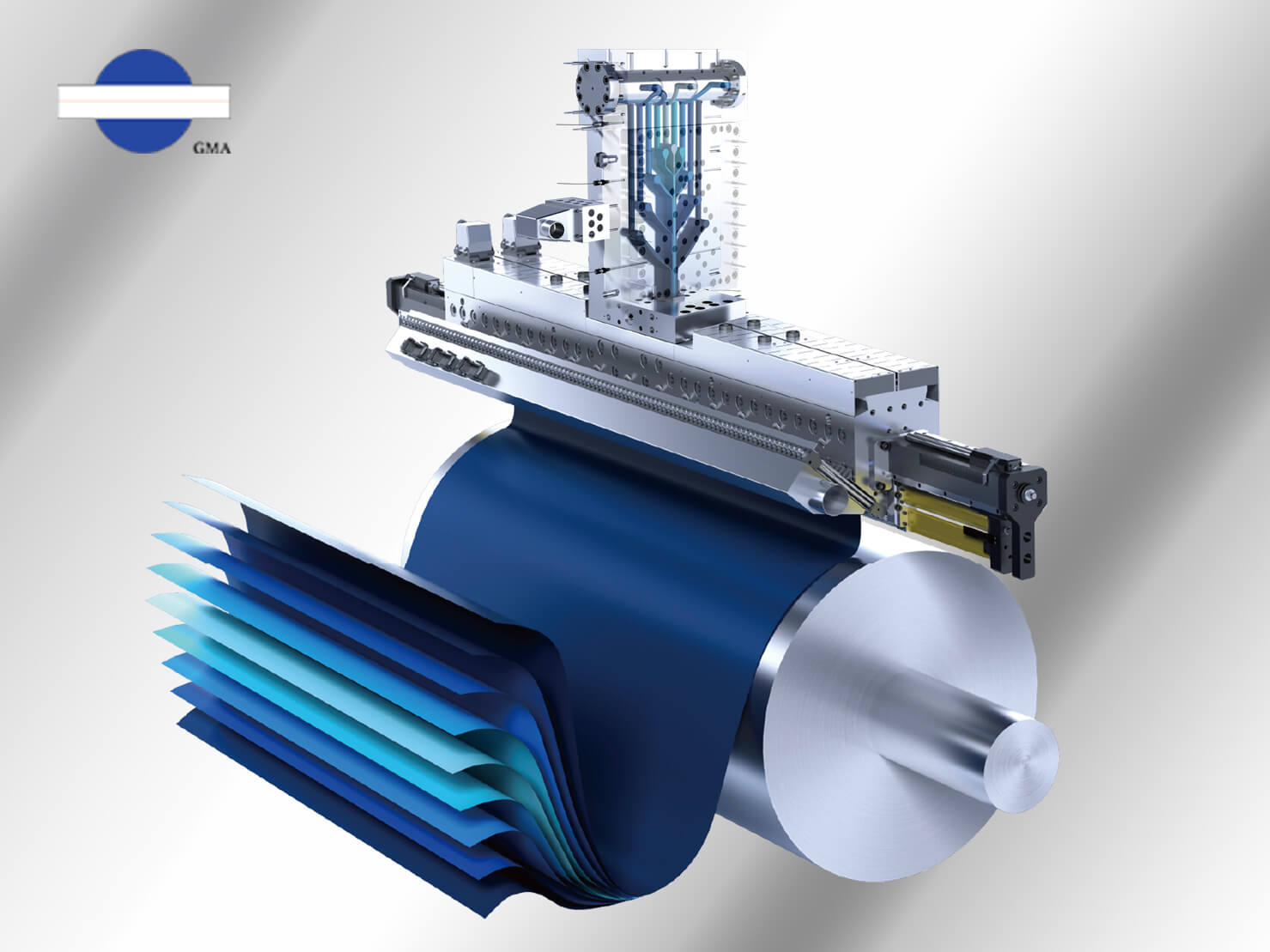

To meet various production specifications, the extrusion die is equipped with basic lip-adjusting bolts for altering the lip gap. Additional options for producing thicker products involve quick lip gap adjustments (with a thickness adjustment range exceeding 3mm) and interchangeable lips.

Typically, the gap can be calculated per turn of the adjusting bolts (with each turn equal to 25mm). The number of bolts required depends on the die width. When adjusting the bolts, it is crucial to evenly distribute the turning force across each bolt. This ensures that the lip withstands uniform stress, thereby preventing bolt sticking or thread breakage."

Lip adjusting bolts、quick lip gap adjustments and interchangeable lip are used for making different thickness product.

There are three types of width-adjusting devices available: external deckle, internal deckle, and a combination of both external and internal deckles.

In the case of sheet dies, manual external deckles are commonly used. Operators adjust the deckle width when the production line is halted for different specifications, and this adjustment is calculated based on the block width (typically 25mm per increment).

For film and lamination dies, manual internal deckle systems are primarily employed. These systems can be easily adjusted during production line operation, either by a handwheel or sleeve, which helps save effort for the operator.

In certain special designs, extrusion dies are equipped with both external and internal deckles to provide greater flexibility.

There are three types of width-adjusting devices available: external deckle, internal deckle, and a combination of both external and internal deckles.

The deckle device comprises numerous small components, and any incorrect or inappropriate operations can result in leakage. Therefore, it is crucial to operate the deckle device in strict accordance with the manual instructions provided

Flow marks and die lines : caused by extrusion die damage

The quality evaluation of the product is significantly influenced by the surface finish when the polymer exits the die lip. Common abnormalities include flow marks (V-shapes or M-shapes, resulting from uneven flow speeds) and die lines (caused by lip damage or the presence of unmelted or burnt material in the chamber.

Learn more : How to solve uneven flow speed in extrusion die? Here is the Answer!

In contemporary times, simulation systems play a pivotal role in optimizing the design and manufacturing of extrusion or slot dies. These systems assist die manufacturers in avoiding unsuitable channel designs. Consequently, the occurrence of uneven flow speeds has significantly decreased, unless there is a change in the customer's formula.

Die lines typically result from damage to the die lip or the presence of unmelted and burnt polymer. To address die lines, the die must be opened for cleaning to troubleshoot the issue. However, repairing lip damage can be a challenging task. Depending on the extent of the damage, different treatment approaches are required. A specialized repair process is employed to save both time and cost, and in cases of severe damage, re-chrome plating may be necessary

Microscopic Examination of Die Lip Damage

Damage to the die lip is often the result of external forces, such as the incorrect use of cleaning tools or mishandling when opening the die for cleaning without adequate protection for the lip, leading to collisions and damage.

landing area. Instead, you can simply use suitable tools made of brass or bamboo to remove any polymer residue adhering to the lip. If it becomes necessary to insert a tool into the chamber, it's important to proceed slowly and carefully to avoid damaging the surface of the landing area.

Lip protected cover can avoid from damage

The best practice is to place the extrusion die on a platform when opening it for cleaning. This allows for sufficient space to work comfortably. After cleaning, it's advisable to promptly reassemble the die. If the die is not reinstalled quickly, using a lip protection cover can effectively prevent damage to the lip.

Learn more : All extrusion die issue , let GMA help you.

Modify: Existing die design or structure arises due to variations in product specification and change in the formulation.

Often, when customers have budget constraints that prevent them from investing in a new extrusion die, modifying an existing die becomes a viable option to meet different product specifications or accommodate changes in the formulation. Recently, we had the opportunity to assist one of our customers, K Company, in modifying their older die to produce thicker products.

The original interchangeable lip on the die, which was manufactured in 2012, couldn't meet the new specifications. When the die was returned to the GMA factory, the first step was to assess its current condition. In addition to addressing wear and deformation, we carefully considered the modification process. After applying the appropriate treatments, we successfully adjusted the lip gap from 4mm to 7mm.

Old die is modified to accommodate changes in product specifications, and production continues after modified the die lip opening.

Another customer, F Company, faced an issue with their old die related to steel fatigue. Due to continuous long-term operation, the precision of the adjusting bolts (push-only) significantly deteriorated. After conducting a thorough inspection and assessment, we decided to modify the type of adjusting bolts to both pull and push, effectively reducing steel wear and tear. This modification extended the extrusion die's lifespan, making it easier for the customer to operate and achieve better performance.

Many customers inquire about the possibility of modifying the die channels when their formulations change. Initially, we employ simulation to evaluate the feasibility of channel modification. Typically, minor adjustments to the channel are feasible and can be implemented to accommodate formula changes.

At present, we offer comprehensive evaluation, inspection, and repair services for extrusion dies of all brands. Die modification is often more challenging than many people anticipate, primarily due to constraints posed by the original design and the current usage condition of the extrusion die. For suppliers lacking proficient design and processing capabilities, die modification may not be a viable option.

Learn more : Do you know 5 points of extrusion die repair and maintenance?

In today's rapidly changing market, the ability to promptly and effectively meet customer expectations often determines who secures more business. As the saying goes, 'Opportunity favors the prepared.' With the fourth quarter approaching, the question is: Are you prepared to seize more opportunities?

If you require professional evaluation or repair services for your existing extrusion die, please don't hesitate to contact us for further information. We stand ready to provide you with robust support.