Unlocking the Three Secrets of Co-Extrusion Feed block

2023.12.29

In

the extrusion process, co-extrusion is a widely employed technique that

cleverly combines two or more different plastics to form multi-layered plastic

sheets or films. The primary purpose of using this technique is to combine the

characteristics of various plastics, enhancing physical and mechanical

properties, as well as meeting specific product requirements such as

transparency, temperature resistance, or cost reduction.

There

are two main methods of co-extrusion : using multi manifold dies and the

well-known combination of feed block with extrusion die . The differences

between these two methods are as below:

|

Multi manifold extrusion die |

Feed block with Extrusion dies |

|

|

Number of Layers |

2-5 layers |

2-11 layers |

|

Applicable Plastics |

Temperature difference of 20 degrees or more |

Plastics with similar temperatures |

|

Operation Method |

Different plastics directly enter separate mold cavities and combine in the mold forming area |

Different plastics enter the layering device, combine within the layering device before entering the mold |

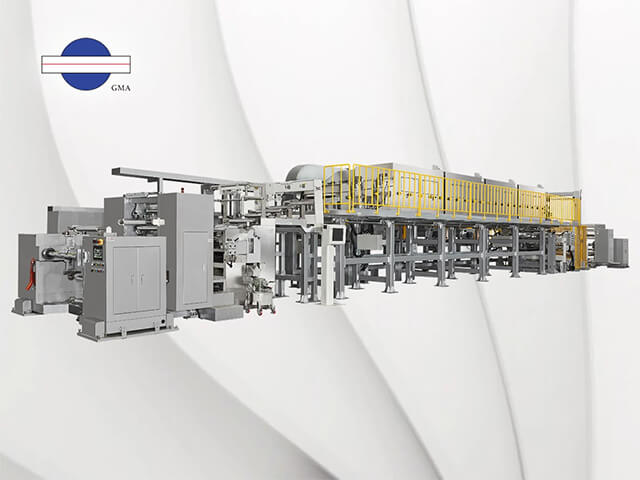

Co-extrusion

in two ways: (Left) Multi manifold extrusion dies, (Right) Feed block with

extrusion dies

Co-extrusion

in two ways: (Left) Multi manifold extrusion dies, (Right) Feed block with

extrusion dies

The

feedblock plays a crucial role in co-extrusion and its operation can be

summarized in three letters: DCA

D: Division

The

feed block is designed based on the placement and quantity of the

extruders, allowing for various inlet sizes and positions. The internal

channels of the feed block are designed according to the structure and

proportions of the product, ensuring that different plastics can enter and

stack in the feed block based on the set ratios. For example, a two-layer

structure implies two internal channels, a three-layer structure has three

channels, and so on.

inlets

and channels in the feed block designed based on the extruder and product

structure.

C:Combination

A:

Adjustment

The feed block features two adjustment tools to facilitate achieving optimal layering effects. The most commonly used tool is the adjustment lever, used to finely tune layering proportions. It functions like a flow valve, altering the flow rate in the internal channels. For instance, it can adjust the material ratio from 15% to 10% for a single layer.

Another

tool, the distribution pin, is used in specific situations to optimize

interfaces in each layer. In cases where uneven layer interfaces occur despite

uniform product thickness, the distribution pin allows for minor adjustments.

In

addition, to accommodate various changes in product structure, the feed block

can be used in conjunction with a selector to alter the direction of the

internal flow paths, offering several different structural variations. This

allows for product diversification in the simplest manner. For example, a

two-extruder, two-layer structure (AB) can be transformed into a two-extruder,

three-layer (ABA) structure by using a selector.

The

feed block includes different adjustment tools for fine-tuning layering

proportions.

The

feed block, playing a crucial role in the co-extrusion process, allows for the

optimization of layering quality through meticulous adjustments. Whether using

a feed block with extrusion die or multi- manifold extrusion dies, adept use of

co-extrusion technology provides a flexible and effective solution for the

development and production of plastic products.