Enhance PPF Quality: Focus on TPU Film Coating Production and Composition

2024.07.23In recent years, the car market has not only seen a surge in electric vehicles but also a trend in car protection films. The driving force behind this new trend is the TPU protective film, known in the industry as "PPF" (Paint Protection Film). It boasts high-level protection features such as UV resistance, oxidation resistance, corrosion resistance, and self-healing capabilities, effectively replacing traditional PVC protective films.

The growing demand for PPF has significantly increased the demand for TPU films. Only through well-designed production lines can high-capacity and high-quality films be produced.

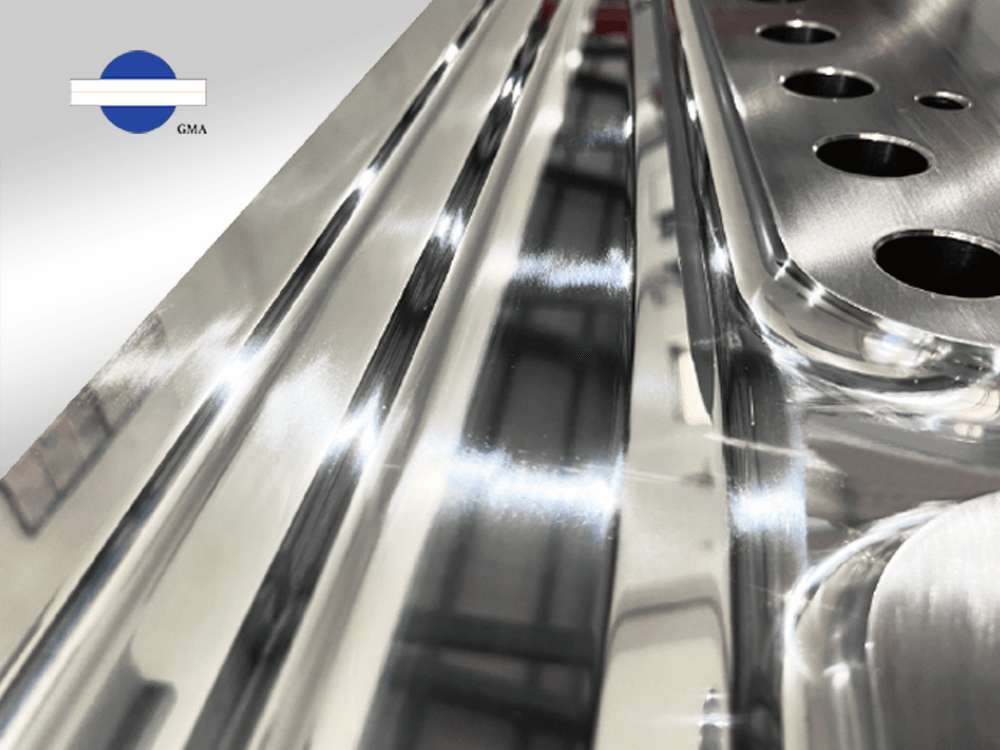

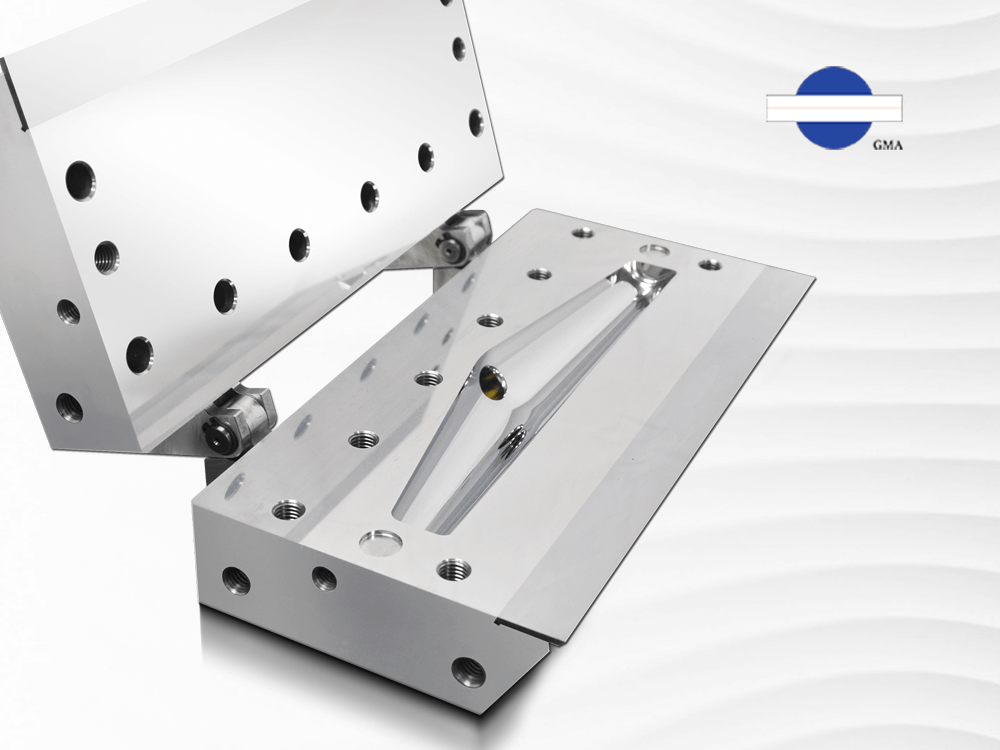

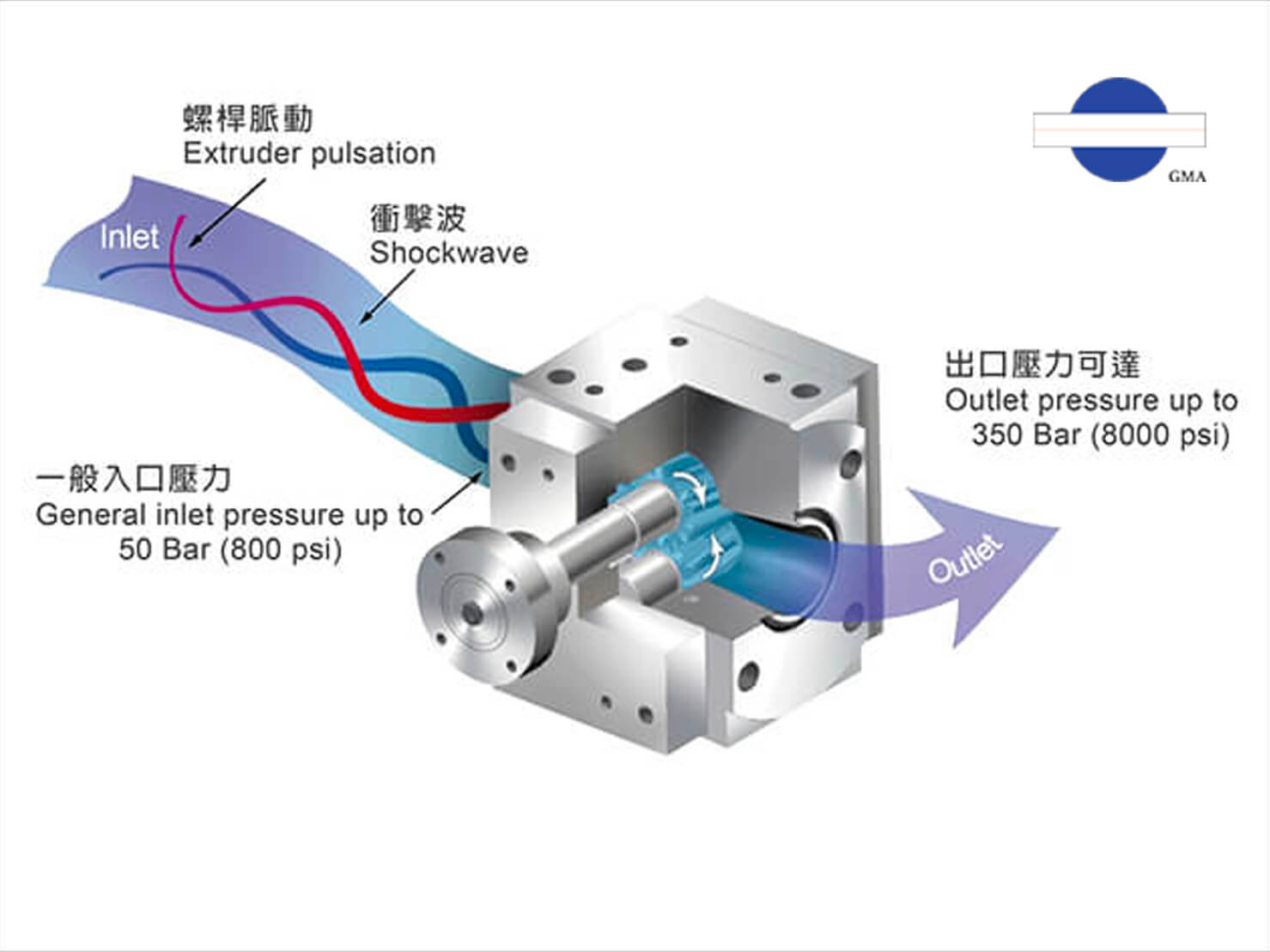

High-quality PPF requires 100% TPU film. The inherent high transparency and durability of TPU film already give it a significant advantage in the protection film market. However, TPU raw material is an elastomer with poor stability, which makes it highly susceptible to changes in temperature that affect its flow ability. Additionally, during production, it is crucial to ensure the film is dry (with a moisture content below 0.01%). TPU film also has issues with easy degradation and yellowing. Although the production process may seem simple, every detail, from the design and processing of the hardware production equipment to the control of actual production conditions, is important. For instance, in the TPU film production line, the extrusion die used for shaping must employ special processing techniques to prevent sticking or tearing of the TPU film.

When extrusion dies are used in the production of TPU films, they need to undergo special processing treatments to ensure the quality of the film.

Read more: TPU Material and Dies: The Ideal Combination for Modern Manufacturing

In addition to high-quality TPU film, the true enhancement of PPF value in the coating process. These coating layers, known as functional coatings, increase the functionality of the film itself. This is why the coating is considered the core factor determining the quality of PPF. The adhesive coating that contacts the car body is crucial, with high-quality PSA (pressure-sensitive adhesive) being commonly used. This ensures the film can adhere seamlessly to the car body and be removed without leaving residue when replaced. More importantly, it enables the PPF to achieve self-healing properties, allowing it to stretch and return to its original shape. This self-healing characteristic helps maintain the film's appearance over time, making it one of the most favored features of PPF in the market.

PPF are primarily composed of TPU films combined with functional coatings to enhance and increase the film's functionality.

The outer coating of PPF is designed to enhance its scratch resistance and wear resistance, protecting the car's paint from scratches, debris, and environmental damage. This not only maintains the car's aesthetic appeal but also helps preserve its value. Therefore, every detail of the coating process, including the coating equipment, adhesive selection, and production conditions, is crucial. To ensure high-quality coating, the process must be carried out in a strictly controlled cleanroom environment.

The coating of TPU films is a key factor affecting quality. The design of the coating production line for PPF must meet high standards, and the entire process must be conducted in a cleanroom environment.

Read more: Let us work together to create more possibility of coating technology

PPF has become an essential component for car protection. As the market continues to expand, many original film manufacturing companies are actively upgrading their equipment and optimizing their processes. Both PPF installers and car enthusiasts are increasingly demanding higher quality and paying more attention to product composition and manufacturing processes. High-quality TPU film combined with excellent coatings ensures that PPF, despite its high market price, can provide a lifespan of five to seven years. For these perfection-seeking consumers, every detail is meaningful and valuable.