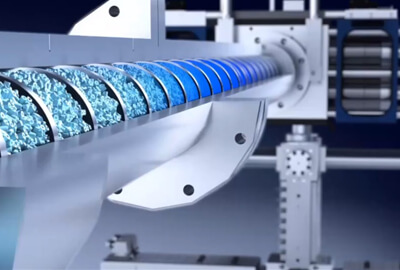

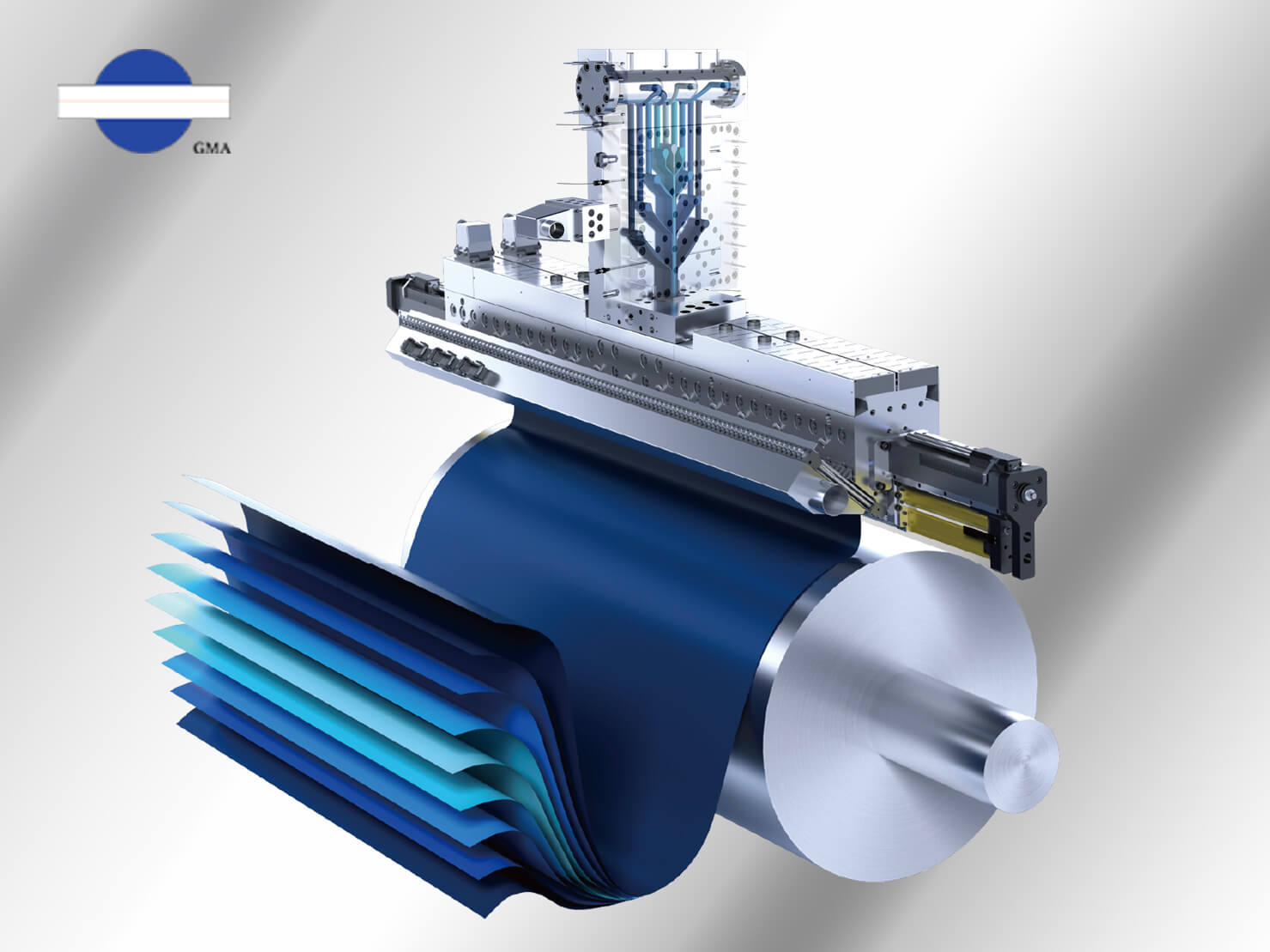

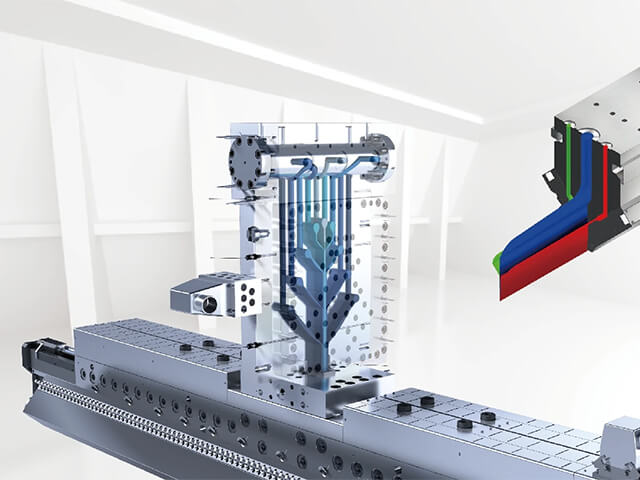

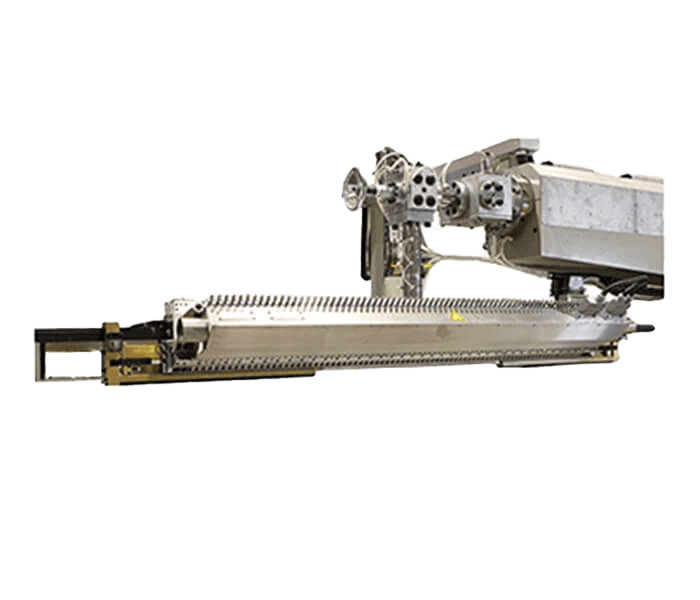

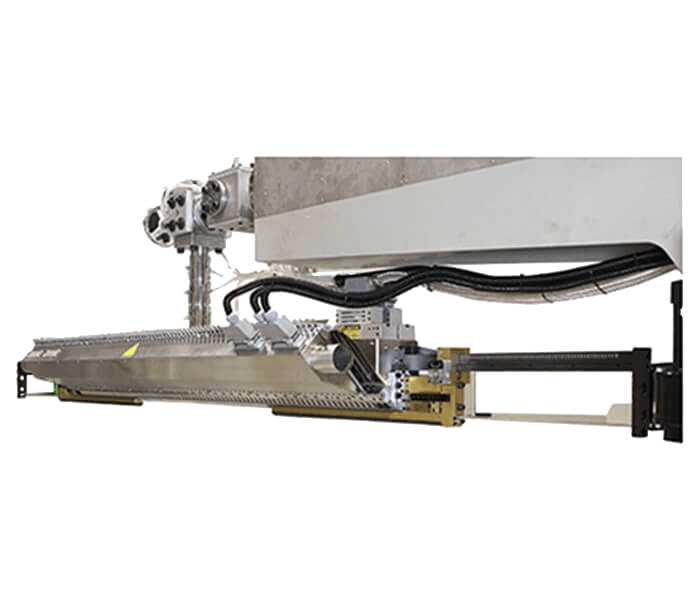

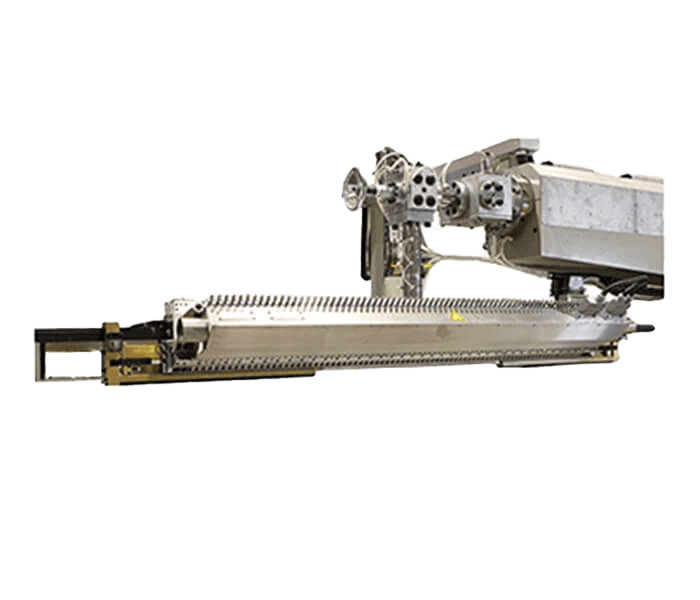

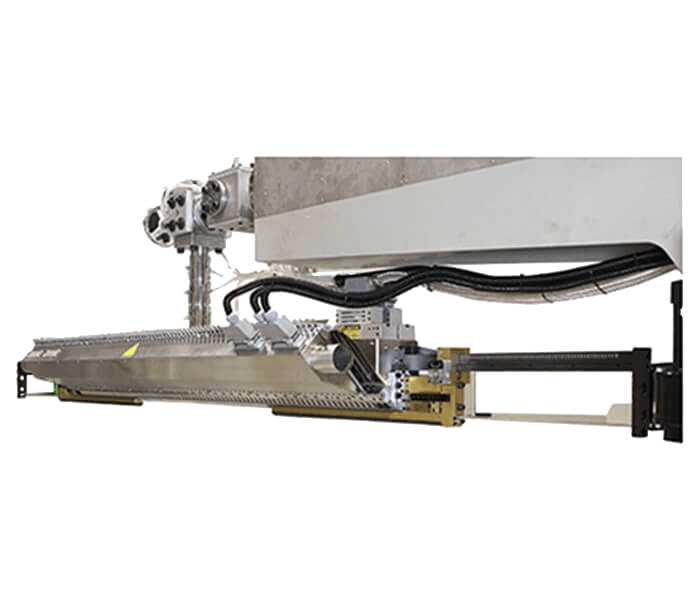

LAMINATION DIES

WITH AUTO CONTROL

AVAILABLE POLYMERS INCLUDING

BOPET, BOPP, Laminating PE

Feature

- Smooth manifold and fast polymer material switch for wastes and costs reduction.

- Trimming-free device for easy scrap thickness adjustment Tuned to trimming free in case of stable flow of PE.

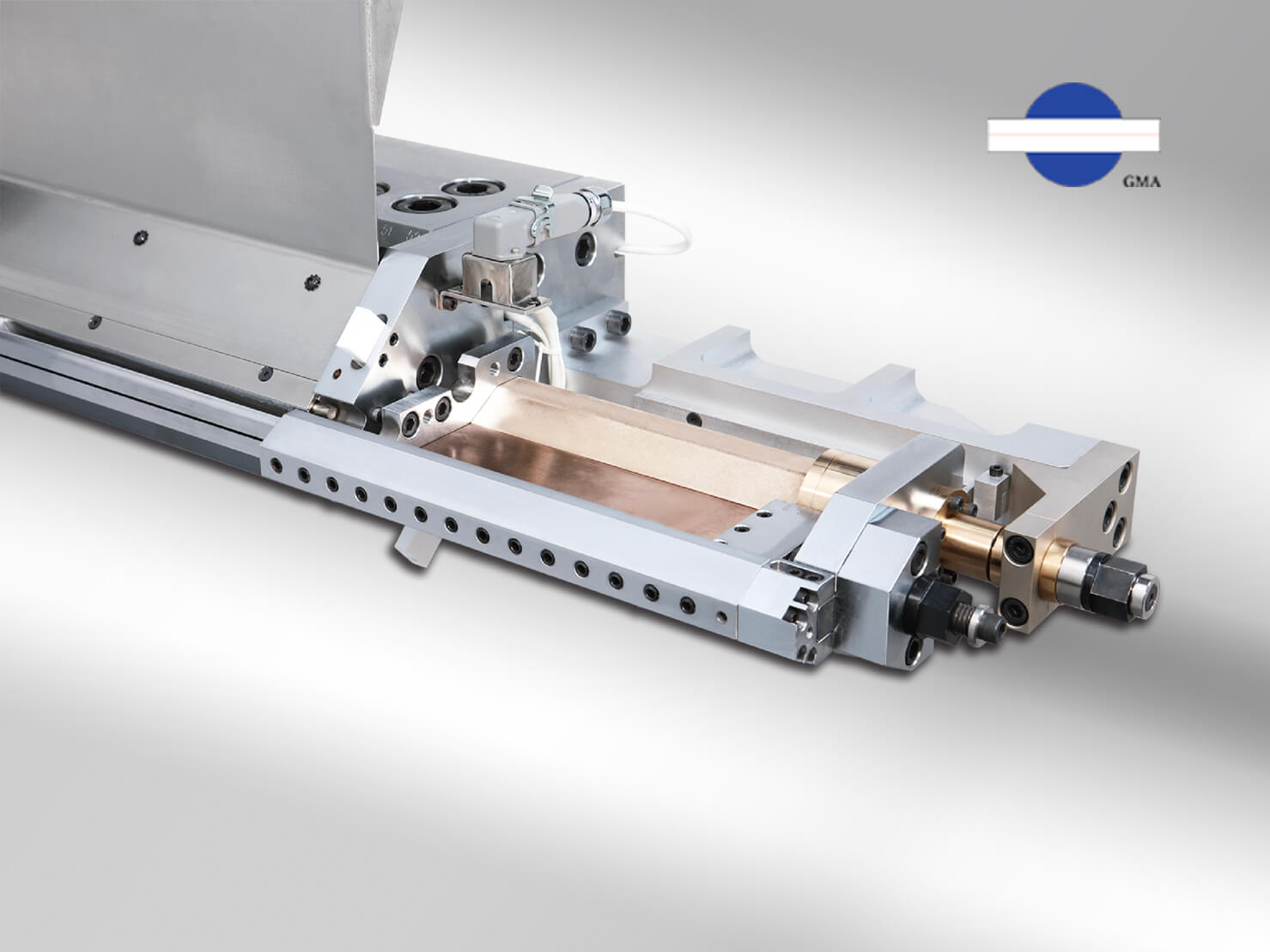

- Damaged die lips may be removed and replaced with new or reworked ones independently.

- Lower air gap energy (close to laminating point), ideal for laminating film.

- Stable die lip after tuning, no further adjustment required (almost).

- Fast side stopper disassembly design for easy die lip cleaning.

- Damaged die lips may be removed for replacement or repair for maintenance costs reduction.

- Work with auto controller.

Catalog Download

Add to

inquiry cart

| SPECIFICATIONS | |

| Width | 500 ~ 5000 mm |

| Finished goods thickness | 0.012 ~ 0.05 µm |

| Extrusion capacity | 100 ~ 500 kg/hr |

Use Field

STATIONERY COMMODITY